Deboning line, Marel (2013)

Working Condition

This in-line deboning line for whole leg from Marel is in a good condition. The line itself is from 2013 but a few modules are from 2019.

This whole leg deboning line has had maintenance every year by Marel.

Are you looking for an in-line deboning line from Marel? This is your chance to get a high quality deboning line for a competitive price!

Breast Cap Deboning Machine, Foodmate, FM 7.50

Refurbished

We have for sale a high-performance Breast Cap Deboning Machine, Foodmate, FM. 7.50 with a capacity up to up to 3000 birds per hour. This machine produces single, as well as butterfly fillets and features an automatic skinning and automatic wishbone remover device.

The breast cap deboner is easy to operate and can be loaded manually by one or two people. Its design allows for adding a transport belt under the machine. The FM 7.50 requires minimal floor space and is easily moved. Will come with a feeding conveyor.

This Breast Cap Deboning Machine, Foodmate, FM 7.50 not what you are looking for or searching for other cut-up and deboning equipment.

Specifications

Model

FM 7.50

Year

2016

Capacity

3.000 bph

Vent cutter, Meyn (2019)

We have a Vent cutter from Meyn (2019) for sale. The machine is dismantled but in a perfect condition.

This Vent cutter, Meyn is designed for high yields to optimize the evisceration process.

The machine has 20 units.

Specifications

Model:

Vent cutter

Year:

2019

Capacity:

9.000 bph

Condition

in perfect working condition

Opener, Meyn (2019)

Working

We have an Opener, Meyn from 2019 for sale. This machine has 20 units and is in a perfect working condition, due to preventive maintenance program. Optimize your speed with the Meyn Opener in your poultry processing line. Engineered for optimal hygiene and minimal maintenance, the Meyn Opener ensures clean cuts and improved yield. Upgrade your production line with proven reliability and unmatched quality from a global leader in poultry processing.

Model:

Opener

Year:

2019

Capacity:

9.000 bph

Eviscerator

Renewed

yield.

This Eviscerator, Maestro has 28 units and is built for high-capacity poultry production lines.

Direction: clockwise (right turning)

This Maestro comes with the giblet platform.

Capacity:

9.000 bph

Model:

Maestro

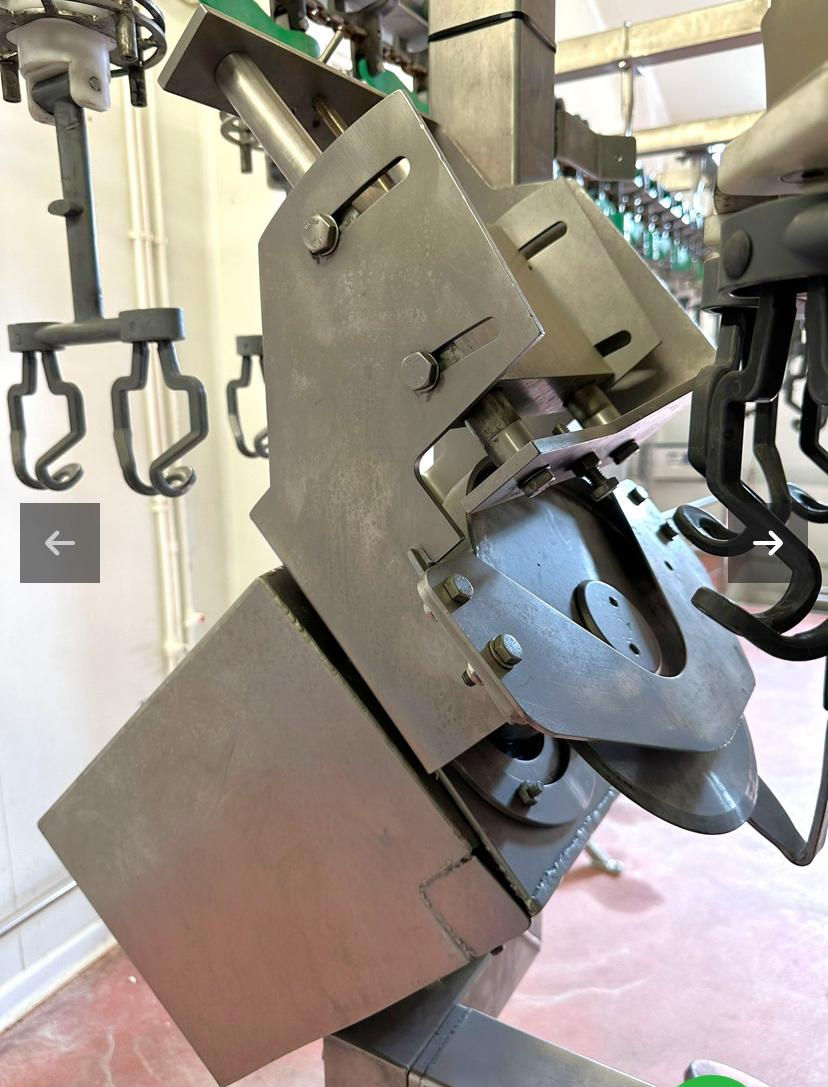

Cut-up line , linco , 4000 bph

Refurbished

Fully renewed poultry cut-up line from Linco with a capacity of 4.000 birds per hour. This Linco poultry cut-up line includes specialized modules:

• Neck skin remover: For precise neck skin removal.

• Whole wing Cutter: Efficiently cuts and separates wings.

• Breast cap cutter: Cuts the breast cap accurately.

• Back cutter: Provides clean back cuts.

• Anatomical leg cutter: Cuts legs with anatomical precision.

• Drumstick cutter: Perfectly cuts drumsticks.

Are you looking for a different poultry machinery? See related products below or click here.

For more details or to discuss your needs, please contact us.

Specifications

Manufacturer

Linco

Capacity

4.000 bph

Condition

Renewed

Meyn Chicken Cut-Up Line

USED

Meyn Chicken Cut-Up Line

The Meyn chicken cut-up line is a technologically advanced solution designed for the automatic processing of chickens into individual parts. Our line is equipped with key cutting stations that ensure precise and efficient separation of chickens into wings, quarters, and legs. Each station is optimized to minimize waste and maximize process efficiency.

Stations on the line:

Wing Cutter Down

This station is responsible for precisely cutting the lower part of the wings. This process allows for quick separation of the wings from the carcass, which is crucial for further processing.

Wing Cutter Up

This station cuts the upper part of the wings. It ensures uniform separation of the wings, guaranteeing high quality of the final product.

NS Cutter Down

This device is responsible for cutting the lower part of the chicken quarters (the leg with part of the thigh). It allows for precise cutting of the lower quarters.

NS Cutter Up

This station cuts the upper part of the chicken quarters (breast with part of the back), allowing for further processing into various components or packaging.

Leg Processor Down

This station processes the lower parts of the chicken legs. This processor enables precise separation of the legs during the cutting stage.

Leg Processor Up

This station processes the upper part of the chicken legs. It performs the crucial cut to prepare the legs for packaging or further processing.

Leg Processor Down – second station

The second station processes the lower parts of the chicken legs, further increasing the efficiency and productivity of the line.

Leg Processor Up – second station

The second station processes the upper parts of the legs, ensuring precise cutting and optimizing production speed.

Foot Processor Up

This station handles the processing of chicken feet, allowing for their separation and processing as part of the production. Chicken feet are often exported to international markets.

Pre Cutter Down

This station prepares the carcasses for further cutting by pre-cutting the lower parts of the chicken. This enables more precise cutting in subsequent stages.

Pre Cutter Up

The second pre-cutting station, this time for the upper parts of the carcass. This station supports the flow of the cutting process and ensures proper preparation of the carcass for further division into components.

Technical Specifications:

Power Supply: 3-phase motor

Main Drive: 3-phase motor

Cutting Precision: Ensured by automatic processors and adjustable actuators

Efficiency: Suitable for lines processing large quantities of poultry

Safety: Integrated safety systems at every station

Our chicken cut-up line ensures fast and efficient carcass processing with minimal product loss. Each station can be adapted to individual production needs, making it a flexible and versatile solution for poultry plants.

Key Benefits of the Chicken Cut-Up Line:

Cutting Precision: Each station is designed with maximum precision in mind to ensure optimal use of every part of the carcass.

High Efficiency: Thanks to the use of two stations for legs and pre-cutting, the line achieves high productivity, reducing processing time and increasing the number of carcasses processed.

Automation: The entire line is fully automated, reducing the need for manual intervention and minimizing errors.

Flexibility: The ability to adjust the settings of each station to the specific needs of the production process.

Safety and Hygiene: The line is equipped with advanced safety systems and easy-to-clean components, meeting the highest industrial standards.

Plucker LM22 - Linco

Refurbished

We have 7 Linco pluckers in stock, that are being used to get rid of feathers. Each standalone plucker can be connected to another to increase capacity.

One of these pluckers could handle a capacity of 1.400 - 2.200 bph after scalding.

All pluckers will come completely refurbished. More photo's and video's on request.

Breast cap deboning equipment - FM7.50

Used

The FM 7.50 Breast Cap Deboning Machine debones up to 3000 breast caps per hour. The machine produces single, as well as butterfly fillets and features an automatic skinning and automatic wishbone remover device. The breast cap deboner is easy to operate and can be loaded manually by one or two people. Its design allows for adding a transport belt under the machine. The FM 7.50 requires minimal floor space and is easily moved.

Contact

Be in the Know

Stay updated with UTECO's latest news, product launches, and special offers by subscribing to our newsletter. Be the first to know about industry insights and exclusive events. Join our community and get the latest updates delivered straight to your inbox! Subscribe now!

Menu

Follow us on

© 2024 by UTECO. Powered and secured by CORE.